Couplings are mechanical devices used to connect two shafts together at their ends to transmit power. They are vital components in various types of machinery, helping transfer rotational motion and torque while accommodating misalignment, reducing shock loads, and minimizing wear and tear between connected components. Couplings can be rigid or flexible, depending on the specific needs of the application. Rigid couplings are used when precise shaft alignment is required, whereas flexible couplings accommodate some degree of misalignment and are better suited for dynamic conditions involving vibration and thermal expansion.

There are many types of couplings including gear couplings, grid couplings, elastomeric couplings, and fluid couplings. Each type offers specific advantages based on the operational environment, torque requirements, and alignment conditions. For example, elastomeric couplings are known for their ability to dampen vibrations and are commonly used in applications where noise and shock absorption are critical.

Flender Couplings

Flender couplings are a specific brand of high-performance couplings developed by Siemens under the Flender brand. Known for their durability, precision, and ability to handle complex operating conditions, Flender couplings are widely used in various industrial applications such as power plants, cement factories, mining operations, water treatment plants, and marine drives.

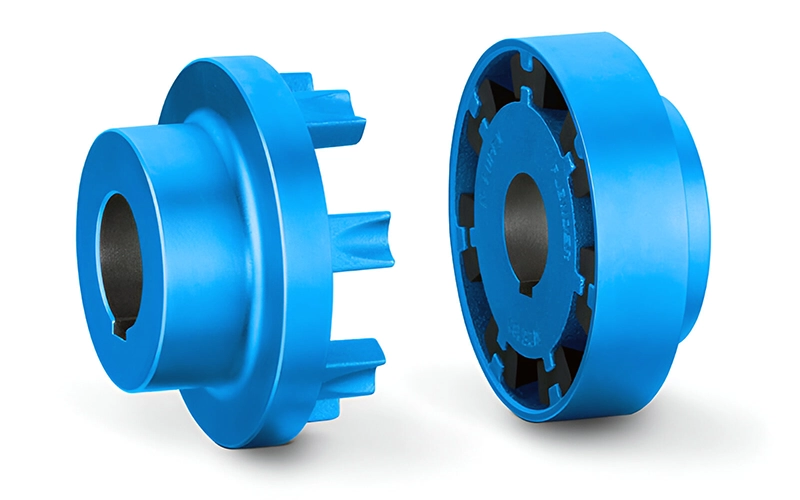

One of the key features of Flender couplings is their ability to transmit high torque levels while compensating for shaft misalignments. They are available in a wide range of types, including gear couplings (Flender GKG), elastic couplings (Flender N-Eupex and Rupex), and torsionally rigid couplings (Flender Arpex). Each of these types is tailored for specific tasks. For example, the N-Eupex couplings are known for their fail-safe design and ability to continue operating even when the elastomer elements are worn, making them ideal for safety-critical applications.

Flender gear couplings are especially suited for applications with high torque and low-speed requirements. They are highly compact, making them ideal for space-constrained environments. On the other hand, the Arpex series of couplings are all-steel, torsionally rigid disc couplings that are ideal for high-speed applications requiring precise torque transmission without backlash.

Flender couplings are also valued for their long service life, minimal maintenance needs, and the ability to work under harsh environmental conditions. This makes them a preferred choice for industries that require high reliability and operational uptime.

In summary, couplings play a crucial role in power transmission systems, and Flender couplings stand out as premium solutions that combine reliability, flexibility, and performance to meet the demands of modern industrial applications.

Couplings, including Flender couplings, are widely used in industrial applications to connect rotating shafts, transmit torque, and accommodate misalignments. They are essential in industries such as power generation, mining, marine, cement, and water treatment. Flender couplings, known for their durability and precision, are specifically used in demanding environments that require high torque transmission and reliability. Applications include pumps, compressors, conveyors, turbines, and gearboxes. Their ability to dampen vibrations, withstand harsh conditions, and reduce maintenance needs makes them ideal for critical operations where uptime and efficiency are crucial. Flender’s range covers both flexible and rigid coupling solutions for various needs.

© 2013 Vertix Co. All Rights Reserved. Leading Supplier Of Foundry & Metallurgical Materials