The wind turbine shaft made from 1.6582 (34CrNiMo6) steel is engineered for high-performance and durability in demanding environments. This alloyed steel is known for its exceptional toughness, fatigue strength, and resistance to wear—qualities that are essential for components exposed to variable wind loads and rotational stress. Specifically used in 660 kW wind turbines, this shaft transmits mechanical energy from the rotor to the generator with high reliability. Heat-treated for enhanced mechanical properties, 34CrNiMo6 offers excellent hardenability and performance under dynamic loads, making it an ideal material for turbine main shafts operating under continuous high-torque conditions.

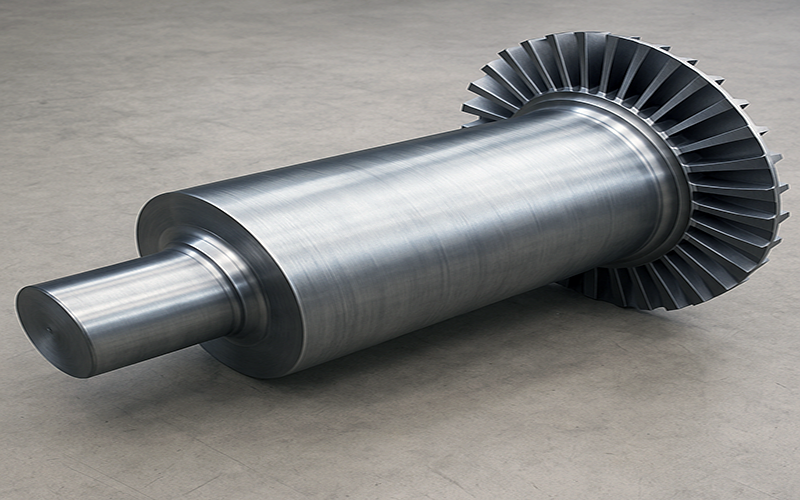

The turbine half-shaft constructed from 1.7709 (21CrMoV5-7) steel, with a diameter of 1200 mm and length of 2540 mm, is a critical component in high-performance turbine systems. This alloy steel is renowned for its high-temperature strength, excellent creep resistance, and durability under dynamic loads, making it particularly suitable for steam and gas turbines. The large dimensions allow it to handle immense torque and rotational stress, while the vanadium, molybdenum, and chromium content ensure thermal stability and mechanical strength over long operational periods. This half-shaft plays a vital role in ensuring the efficient and reliable transfer of mechanical energy in demanding industrial environments.

The Induced Draft (I.D.) Fan Shaft made from 1.6580 (30CrNiMo8) alloy steel, with a diameter of 520 mm and length of 3751 mm, is designed for use in high-power ventilation and exhaust systems, particularly in thermal power plants and industrial furnaces. This high-strength steel offers excellent toughness, fatigue resistance, and mechanical stability under continuous rotational loads. Its nickel, chromium, and molybdenum content provides superior hardening ability and wear resistance, ensuring reliable long-term performance even under fluctuating operational conditions. The shaft’s precise dimensions and material quality contribute to efficient energy transfer and minimal vibration during high-speed rotation.

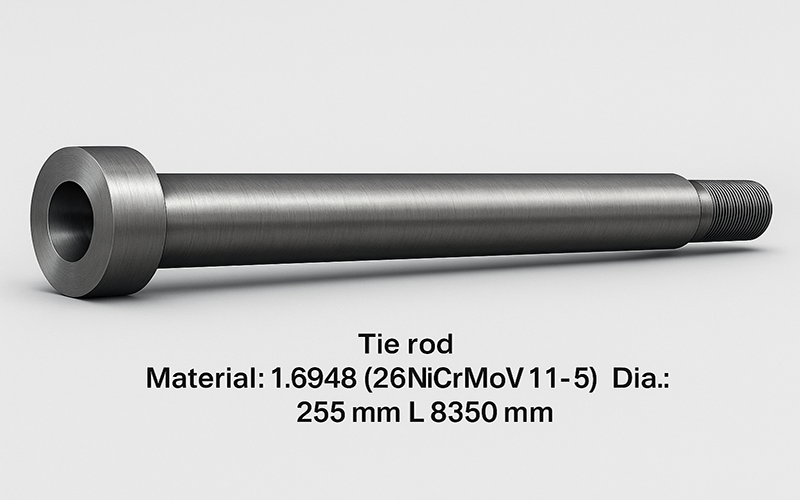

The tie rod manufactured from 1.6948 (26NiCrMoV11-5) steel, with a diameter of 285 mm and an impressive length of 8350 mm, is a high-strength component designed for use in demanding structural and mechanical applications, such as turbine assemblies or large-scale pressure vessels. This alloy steel is known for its excellent tensile strength, high toughness, and superior fatigue resistance, thanks to its balanced composition of nickel, chromium, molybdenum, and vanadium. The extended length and robust diameter allow it to efficiently absorb and distribute axial loads over large distances, making it ideal for applications requiring precise alignment, structural stability, and long service life under dynamic stress conditions.

© 2013 Vertix Co. All Rights Reserved. Leading Supplier Of Foundry & Metallurgical Materials