White cast iron is a type of cast iron known for its hard and brittle nature due to the presence of iron carbide (cementite) in its microstructure. Unlike other forms of cast iron, such as gray or ductile iron, white cast iron lacks free graphite, which makes it exceptionally hard and wear-resistant but also more brittle and less machinable.

White cast iron typically contains 1.8% to 3.6% carbon and 0.5% to 1.9% silicon, along with other alloying elements such as manganese, chromium, and molybdenum. The relatively low silicon content prevents the formation of graphite, leading to a microstructure dominated by cementite (Fe₃C) and pearlite or martensite, depending on the cooling rate and alloy content.

When molten iron solidifies rapidly, carbon in the alloy combines with iron to form iron carbide instead of precipitating as graphite. This results in a hard and brittle structure that gives white cast iron its distinct properties.

Hardness: White cast iron is extremely hard, typically ranging from 350 to 600 Brinell Hardness Number (BHN), depending on its composition and heat treatment.

Brittleness: Due to the high concentration of cementite, it is brittle and prone to cracking under impact loads.

Wear Resistance: The hardness of iron carbide makes white cast iron highly resistant to wear and abrasion, making it ideal for applications where surface wear is a concern.

Low Toughness: The brittle nature of white cast iron means it has poor impact resistance and is not suitable for applications that require high toughness or ductility.

White cast iron is primarily used in applications where wear resistance is crucial. Some of the common uses include:

Grinding Media: It is used in ball mills for grinding materials such as ores, cement, and coal due to its high hardness.

Pump Liners and Impellers: Used in slurry pumps and other abrasive fluid-handling equipment.

Railroad Brake Shoes: White cast iron provides durability and resistance to wear in braking systems.

Mill Liners and Crushing Equipment: These are Common in mining and cement industries where materials need to be crushed under high stress.

White cast iron is a valuable material where hardness and abrasion resistance are required. However, its brittleness limits its use in applications requiring impact resistance or flexibility. Through heat treatment and alloying, its properties can be modified for specific industrial applications.

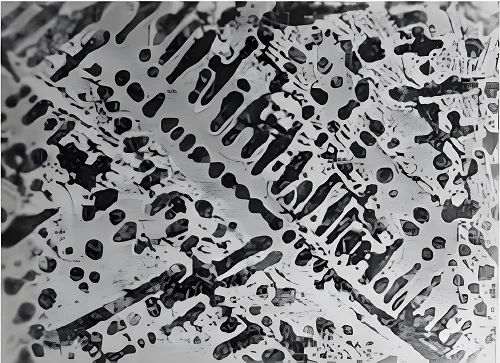

White cast iron has carbideimpurities which allow cracks to pass straight through. It is the cast iron that displays white fractured surface due to the presence of cementite. The cementite which precipitates from the melt forms as relatively large particles, usually in a eutectic mixture, where the other phase is austenite (which on cooling might transform to martensite)

| Parameter | Value/Range | Comments | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Carbon (C) | 3.5-4% | High carbon content promotes the formation of cementite | |||||||

| Silicon (Si) | 0.5 max | Limits graphite formation, ensuring a white microstructure | |||||||

| Manganese (Mn) | 0.3-0.6% | Improves strength and hardness | |||||||

| Phosphorus (P) | 0.05 max | Kept low to avoid excessive brittleness | |||||||

| Sulfur (S) | 0.05 max | Minimized to prevent hot shortness | |||||||

| Chromium (Cr) | 0.3 max | Adds to the wear resistance | |||||||

| C: 3.5-4 | Si: 0.5max | Mn: 0.3-0.6 | P: 0.05max | S: 0.05max |

|---|---|---|---|---|

| Cr: 0.3max |