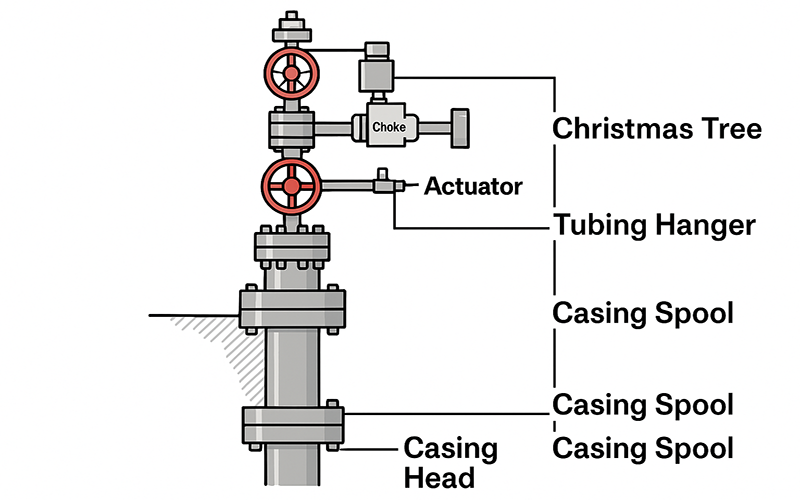

Wellhead equipment provides the pressure-containing interface at the surface of an oil or gas well. It suspends casing strings and connects surface pressure-control devices. The main components include the casing head housing, various spools (casing, tubing, Christmas tree), valves (gate, safety), master valves (upper and lower blocks), and fittings (tees, crosses, adapters, caps, bonnets). Together, they control annular and tubing pressures, support the weight of downhole tubulars, and enable safe production, intervention, and testing.

The casing head housing is the base of the wellhead assembly. It is bolted to the conductor or surface casing and provides the primary pressure seal on the outermost casing string. Above this, the casing head spool allows attachment of additional casing strings or Christmas tree equipment. It contains pressure vents and outlets for annulus access and testing.

The tubing spool—often shaped like a “Y”—suspends the production tubing hanger and seals the tubing-to-annulus space. It features a vertical bore for the tubing and an angled branch for annular access, accommodating gauges, kill lines, and safety valve control lines.

Gate valves at the wellhead control flow through the tubing or annulus. The valve body houses the gate mechanism, while the bonnet encloses the gate stem and packing assembly, providing pressure containment around the stem.

Master valves, also known as master blocks, are full-bore, manually operated gate valves located on the production (tubing) outlet of the Christmas tree. The upper master block sits above the lower one, enabling a double-block and bleed configuration for safe intervention and isolation.

Cross: A four-way fitting used to divert or combine flow streams at the wellhead, often part of the Christmas tree arrangement.

Tee: A three-way fitting directing flow between the wellbore and surface lines, such as choke and kill lines.

Adapter Flange: Provides compatibility between different API flange sizes or pressure classes, allowing the wellhead to interface with surface piping or control equipment.

The cap, or tree cap, seals unused outlets on the Christmas tree. It may be a blind flange or a pressure-rated cap with test connection points for pressure verification.

The subsurface safety valve (SSSV) body is installed in the tubing string and controlled via hydraulic or electrical lines that pass through the tubing spool. Its body houses the closure element that shuts in the well if control pressure is lost.

The bonnet on both the gate valves and master blocks matches the valve body to maintain pressure integrity around the stem. It secures the packing and seals around moving parts.

The lower master block serves as a secondary shutoff below the upper master valve. It is used in conjunction with the upper block during maintenance operations to ensure complete isolation of the wellbore.

The crosshead spool supports the Christmas tree fittings and houses cross outlets. Its cap seals any unused port. Crosshead spools are integral to the Christmas tree assembly, linking all flow control components.